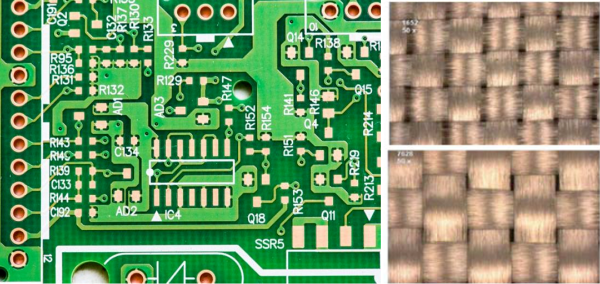

PCB glass fiber

Usually, in order to improve the strength of PCB, glass fiber/cloth is often added to the PCB dielectric layer. Even a very thin PCB can be improved in strength once fiberglass is added. The strength and durability of printed circuit boards formed by mixing and weaving glass fibers with various resins that form circuit board materials will be greatly improved. When the circuit board requires higher mechanical strength, one or more layers of glass cloth can be mixed into the dielectric substrate, and at the same time, ceramic materials are used as fillers to mix together to achieve high mechanical strength. Glass fibers are usually braided and have a higher dielectric constant (Dk) than dielectric materials (and ceramic fillers).

2

Preparation scheme

1、Cutting

PCBs can generally be cut with a diamond cutting blade on a precision cutting machine.

2、Mounting

If there is no special requirement, both fast and slow mounting epoxy resins and acrylic resins can be used for cold mounting of PCBs. For edge protection requirements, it is recommended to use a slow mounting edge protection epoxy resin system.

3、Grinding and polishing

It can be ground directly with finer sandpaper. The correct choice of polishing cloth is related to whether the glass fiber can be clearly displayed. If you use a general polishing cloth, due to the huge difference in hardness between the glass fiber and the matrix resin, it is very likely to cause a large embossment on the polishing surface and cause the metallographic image to be blurred. Therefore, it is recommended to use a hard and elastic polishing cloth for polishing.

4、Trojan recommends the following grinding and polishing process for reference:

|

Step |

1 |

2 |

|

Prepare the surface |

SiC sandpaper |

GF polishing cloth |

|

grain number |

P400~P2500 |

1μm diamond polishing fluid |

|

cooling lubricant |

water |

/ |

|

Single sample load/N |

23 |

21 |

|

Time/s |

120 |

120 |

|

Grinding head speed/rpm |

80 |

80 |

|

Lower disc speed/rpm |

300 |

100 |

|

Direction |

Same direction |

Same direction |

PCB glass fiber 100×

PCB glass fiber 200×

中文简体

中文简体 英语

英语 西班牙语

西班牙语 德语

德语

.jpg?imageView2/2/w/400/format/jpg/q/75)